NEM - Center of Materials Testing

Providing physical and mechanical testing services on construction materials including concrete, cement, aggregates, steel reinforcement, prestressed steel reinforcement, structural steel, geosynthetics, gullies, manhole covers, aluminium, coatings and many others. Provide outdoor environmental monitoring, such as noise, air quality (dust), etc.

Quality Control of Concrete

Concrete is the main material for civil engineering. Selecting concrete with appropriate workability, mechanical properties and durability could be the foundation for assuring the engineering quality. The method of quality control for concrete in Macao is including: certifi cation of concrete for concrete batching plant and quality supervision for specifi c concrete of engineering project.

• Certification of Concrete for Commercial Concrete Batching Plant

Certifi cation of concrete is jointly participated by DMC and DQN. Factories, which have obtained certifi cation, comply with the quality management system and technical requirements specified in the Rules of Scheme for Certifi cation. The purpose of certifi cation is to verify whether factories have the ability to manufacture products that comply with the requirements of “Macao Standard for Concrete”, “Approval & Reception Procedure for Ready Mixed Concrete” and “Rules of Scheme for Certification”. Now, the certified manufacturers is including Macao local concrete plants, concrete batching plants for Hong Kong-Zhuhai-Macao Bridge project and light rail projects precast segment.

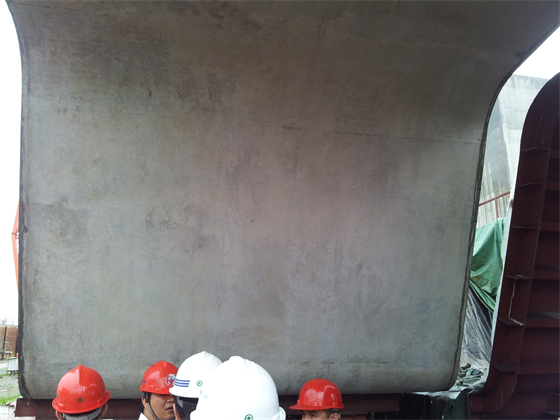

HZMB Project—Certifi ed concrete batching plant on ship

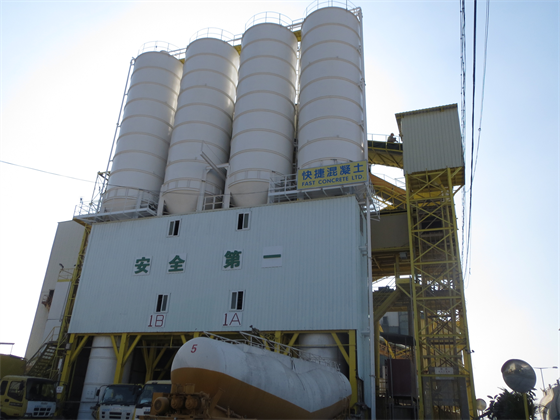

HZMB Project—Certifi ed concrete batching plant

Precast unit of LRT Project—Certifi ed concrete batching plant

Certifi ed concrete batching plant of Macao

• Quality Supervision for Specific Concrete of Engineering Project

The quality of specifi c concrete which did not be certifi ed should be supervised in accordance with “Approval & Reception Procedure for Ready Mixed Concrete” and requirements of project.

Every engineering project should implement trail mix test for the specifi c concrete mix design and testing for raw materials of concrete before using it. During the construction, it is also necessary to monitor mechanical properties, durability and hazardous substances of the concrete through regular sampling and testing.

Public housing project in Seac Pai Van

LRT project

-Trial Mix Verifi cation of Concrete

After the approval of the mix design of concrete, it is required to implement three trail mixes in three dates and take samples within the batch to prove the concrete mixture and harden concrete are all meet the relative requirements for the quality assurance purpose. In addition, it is necessary to verify the applicability of the production process and facilities.

Despite of the verifi cation of the concrete strength, the permeability and resistance of chloride ions should be also verifi ed according to the engineering requirement.

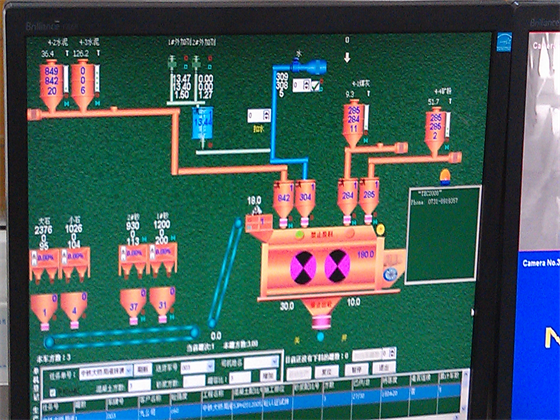

Verifi cation for the accuracy of material quantity

Measurement of temperature of fresh concrete

Measurement of the slump of fresh concrete

Sampling of the specimens for strength testing

Audit for specimens curing room

Audit for storage area of aggregate

-Quality Control of Constitute Materials of Concrete

For ensuring the quality of concrete, the fi rst matter is importance to control the quality of component materials of concrete, such as cement and other cementitious materials, aggregate, admixtures and mixing water.

Cement and Other Cementitious Materials

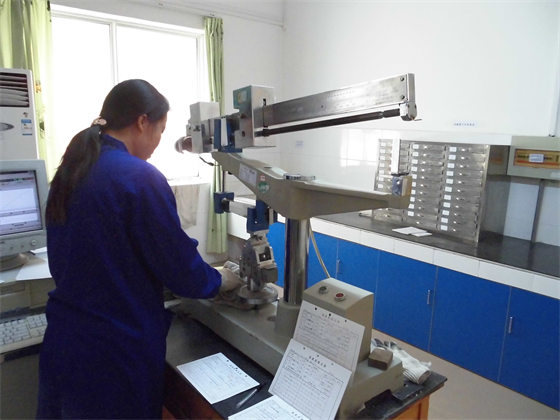

The performance of cement and other cementitious materials should be tested according to Macao Standard for Cement and Macao Standard for Concrete.

Mixing mortar for strength test

Shaping specimen for strength test

Setting time

Soundness

Chemical test for cement

Chemical test instrument for cement

Aggregate

According to Macao Standard of Concrete for testing.

Sieve analysis test

Water absorption test

Flakiness particle content and elongation particle content test

Abrasion by LA machine test

Crushing strength test

Potential reactivity with alkalis

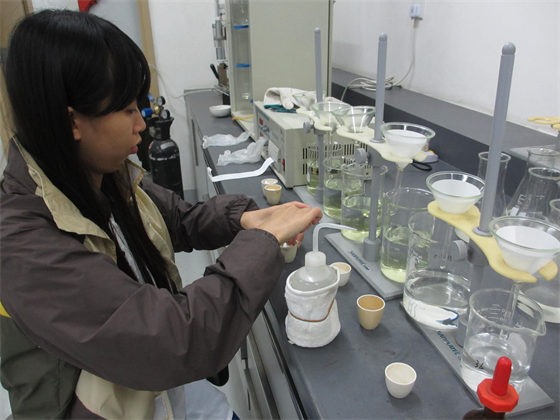

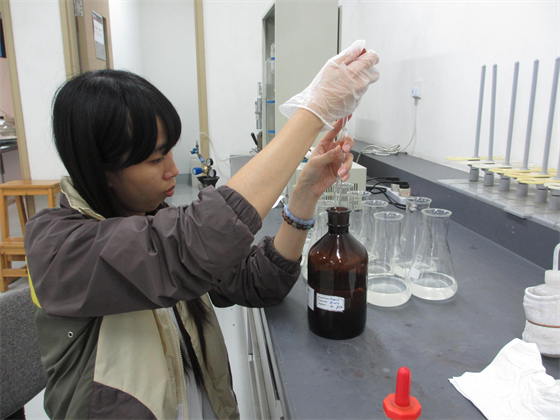

Chloride ion content test for river sand – Filter

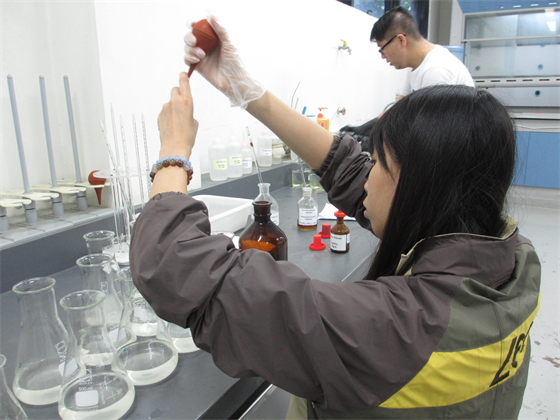

Chloride ion content test for river sand – Titration

Mixing Water

Mixing water from the public supply can be used without any need for testing.

Admixture

According to Macao Standard of Concrete for testing.

Density test for admixture

Density test for admixture

Chemical test for admixture

Chemical test for admixture

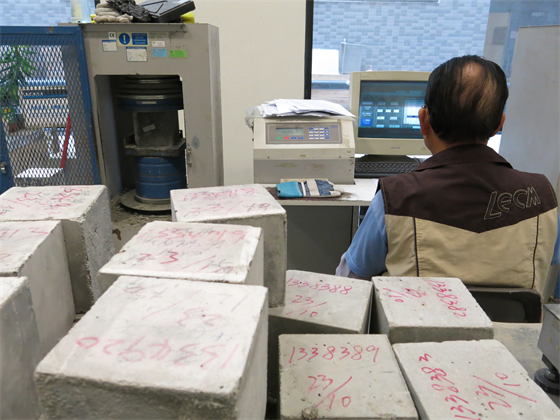

-Hardened concrete strength test

Normally, the main consideration of the mix design is compressive strength which is one of the characteristics to sustain the construction safety and applicability. According to the Macao concrete standard, it is required to take cubic sample of concrete for each casting for verifying the compressive strength.

The coring method is using to take sample for evaluation of in situ concrete strength or the acceptance for the compressive strength of PHC pile and concrete kerb.

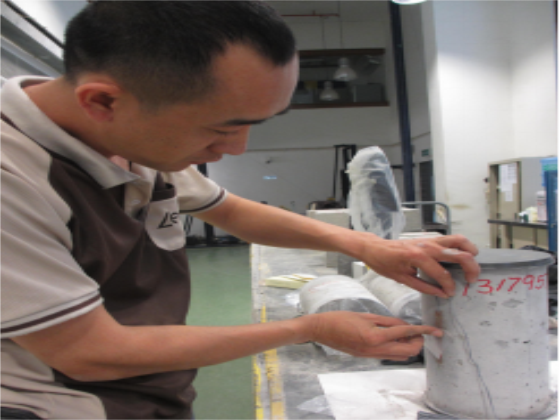

Measurement for dimension

Weighting

Compressive strength test

Compressive strength test

Measure the dimension of core

Capping of core surface

Compressive strength test of core

• Durability of concrete- impermeability

Waterproof concrete is used for preventing the leakage of the rooftop, water tank and basement structure. Hardened concrete which is under water pressure could be tested for the waterproof ability by the impermeability test.

Impermeability test under water pressure

Measurement for the depth of permeability

• Durability of concrete-Resistance of the penetration chlorideion

The corrosion of the steel reinforcing bar is the major factor that shorten the service life of concrete structure. The free chloride ion is strongly associated with the corrosion speed of steel reinforcing bar. Macao is a place surrounded by sea, so the permeability of chloride could be used for evaluating the durability of reinforced concrete structure when it is directly expose in the air and sea water.

Electrical indication Method

Diffusion coeffi cient of chloride ion

• Concrete workability-Creep Strain Test

Creep strain, the deformation level of concrete keep increasing by time to time during a long period loading of concrete. Creep strain could cause the enlargement of deformation (deflection) for the structure (component). In addition, it could affect the normal function of the structure and cause the loss of the pre-stressing force of the pre-stressed structure.

Installation for strain gauge

Testing for creep strain on the machine

Taking data of creep strain

Uniaxile compression frame for creep test

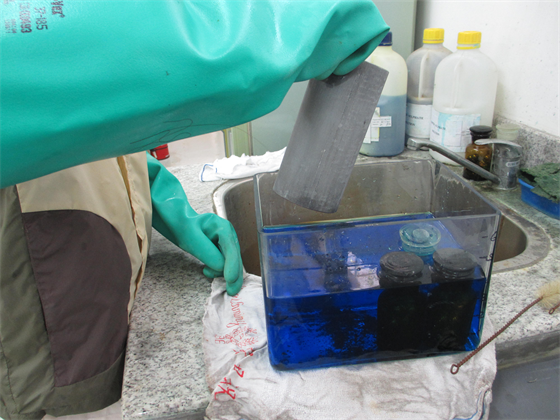

• Hazardous substances control – Chloride ion content

When the raw material has chosen improperly, could lead to concrete contain high level of chloride ion. High chloride ions will destroy the passivation layer of the rebar surface, which can cause damages to the rebar’s seal protection. Long-term effects will lead to reinforcement corrosion and concrete cover broken. Hence the chloride ion content is needed for concrete.

Sampling from the structure

Acid-soluble chloride ion content test

Quality Assurance of precast segments

Precast segments are the most important structural element of viaduct for Macao LRT project. It should not only bear the stress from the upper structure but also meet the requirements of appearance quality, and the service life of structure for Macao LRT project requirement is required to achieve 100 years. Therefore, the best quality of inherent performance, appearance and durability are required for precast segments. The precast segments are mainly prefabricated in professional manufacturer or the precast yard which is specially established for Macao LRT project.

For ensuring the quality of precast segments, DMC and CA jointly perform the quality control for production process, to ensure that the all precast segments which will be delivered for establishing in Macao shall strictly meet the quality standards.

• Expressly permitted production basic conditions

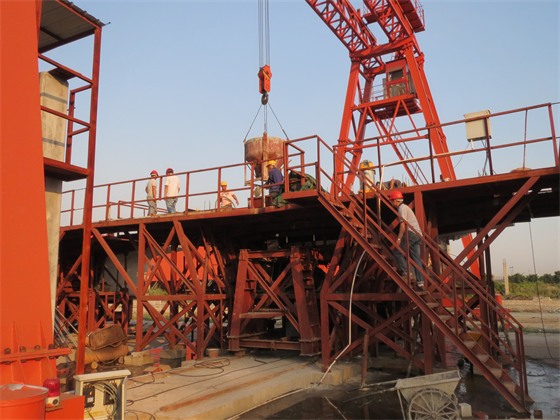

The all concrete batching plant of precast yard must be certifi ed according to Ready-mixed Concrete Certifi cation of Macao, and ensuring that the quality of constitute materials and concrete comply with the requirement of Macao code.

Concrete certifi cation

Certifi ed concrete batching plant

• Strictly verify the application of raw materials

All the raw materials to be used shall be tested and fulfill the specification. The aggregate for concrete must be separated from others and stored independently, to achieve the target as “specifi ed material to be specifi cally used”. The consumption for raw materials will be regularly traced to avoid the unqualified materials such as marine sand is to be used in the project.

Independent, separated store for aggregate

Specifi ed aggregate for precast segments of Macao LRT project

The qualifi ed steel bars

The qualifi ed cement

• Strictly supervise the quality with detection method during construction

The raw materials, concrete and products shall be took samples for test according to the Rule of Concrete Certifi cation, project requirements and the relevant Macao code not only by DMC but also by the approved independent 3rd party Lab. The quality for precast segments shall be comprehensive, timely and effective controlled with the double testing supervision mechanism.

Sampling steel bars on site

Steel bar testing

Sampling aggregate on site

Aggregate testing

Sampling fresh concrete

Compressive strenght test for concrete

• Strictly control the quality of production process

For ensuring the quality of precast segments, the reinforcing cage, the formwork, the topographic survey and the fresh concrete must be performed acceptance procedures, irregular spot checks will be performed to monitor the quality by DMC. Especially pointed out that the temperature of concrete pouring into formwork is required not more than 30 o C, this requirement is stricter than the relevant Macao code, it could prevent temperature crack from occurring to effect on the durability of the structure.

Reinforcing cage acceptance

Formwork acceptance

Inspection for topographic survey apparatus which to be used for geometric control

Inspection for the temperature of concrete pouring in formwork

Inspection for slump

Supervision for concrete pouring on site

• Specifi ed detection method for 100 years durable concrete

Test methods and acceptance criteria for durability performance of concrete are be defined according to the exposed external environment condition in Macao and 100 years service life of the structure. It can be quantitative evaluation for concrete durability with the chloride ion migration index or electric flux, and facilitate to uniformly supervise the quality of the project.

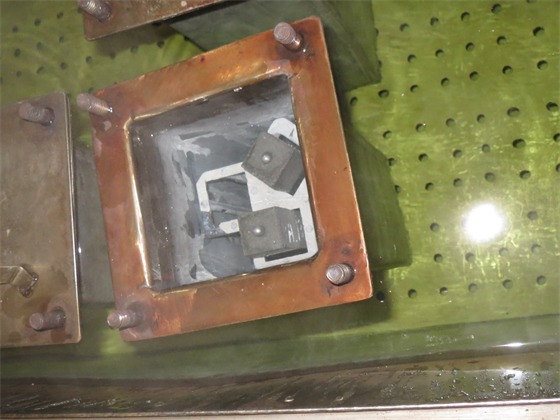

Test of concrete to resist chloride ion penetration

Completed test samples for concrete to resist chloride ion penetration

• Perform “First Mechanism”— strictly control the appearance quality

“First Mechanism” mean that the first precast segment must be inspected and accepted by supervisor and LECM during production in accordance with the relevant requirements. The purpose is that according to the project requirements of appearance quality and the relevant code, the fi rst precast segment is inspected for appearance, meanwhile the acceptance criteria and the allowed treatment scope for appearance will be defi ned. At last the fi rst qualifi ed precast segment should be as a model of appearance acceptance when mass production.

Inspecting external appearance quality

Inspecting inner appearance quality

• Perform product test — strictly control the quality of segments before delivery

A batch of precast segments is every accumulated 50, took sample from finished segments to perform rebound test, chloride ion content test and cover thickness test. By passing the product test, the batch of precast segments can be allowed to deliver to Macao site for establishing, ensuring to comply with the requirements of in-situ quality.

Rebound test for product

Cover thickness test for product

Taking sample for chloride ion content test of product

Taking sample for chloride ion content test of product

Quality Control of Steel Materials

Quality Control of Steel Materials is daily major testing for DMC. The purpose of quality control is to verify products comply with NORMA DE AÇOS PARA ARMADURAS ORDINÁRIAS and REGULAMENTO DE ESTRUTURAS DE AÇO PARA EDIFÍCIOS.

• Steel bar test

Steel test

Steel test

Steel test

Test samples of coupler

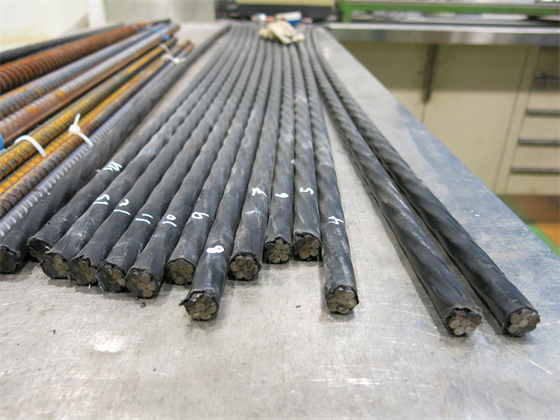

• Wires-strand for prestressing

Samples of wires-strand

Testing wires-strand

• Material for Steelwork

Steel for pile end-plate

Material for Steelwork

Bolt for Steelwork

Quality Control of Metallic Coating and Painting

For ensuring the durability of structures, coating and painting on the surface of metal and concrete generally shall be inspected in accordance with the requirements of the relevant code, in order to achieve the purpose of quality control for coating and painting.

• Coating Thickness test

Coating thickness test for concrete structure

Painting thickness test for steel structure

Coating thickness test for aluminium alloy

• Adhesion force test for coating

Test nail installation

Adhesion force test

• Uniformity of Galvanizing Coating

Uniformity test

Uniformity test

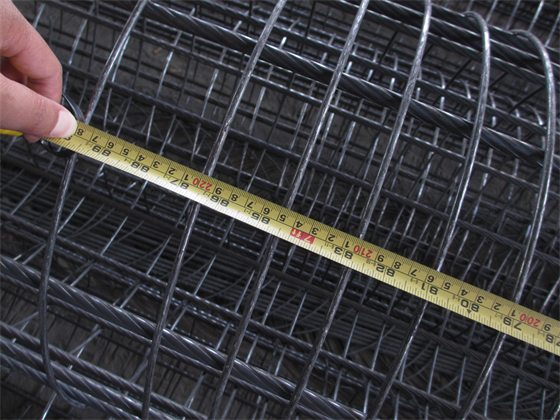

Quality Control of Geosynthetics

Geosynthetics used in civil engineering, physical properties and mechanical properties should be tested in accordance with the requirements of the relevant code, in order to achieve the purpose of quality control for the materials.

Geotextile samples

Geodrain samples

Mechanical properties test for geosynthetics

Quality Control of Manhole Top and Gully Top

Manhole top and gully top used in road or sidewalk, dimension and mechanical properties should be inspected in accordance with the requirements of the relevant code, in order to achieve the purpose of quality control for the materials.

Manhole top

Loading test

Gully top

Loading test

Test of Rock Core

Test of rock — test results are one the basic reference for pile foundation design

Production samples

Production samples

Compressive test

Testing samples

Point load test

Point load tested samples

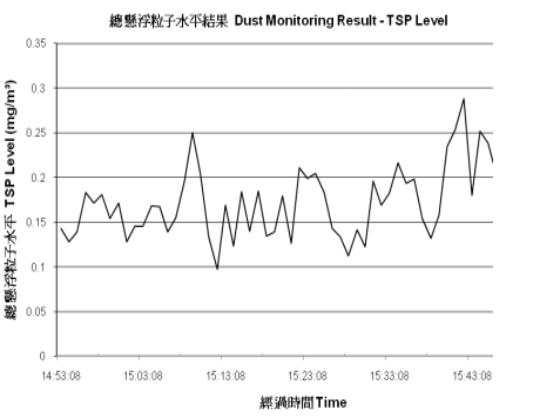

Environmental Monitoring

As everyone is concerning about the environment nowadays, however people can only describe the level of environmental pollution with their own sensation. For this reason, there have to be one independent and professional crew for conducting environmental monitoring, which will statistically refl ect the level of pollution. Therefore, DMC has started the project of environmental monitoring since May 2013, which the environmental monitoring includes both Air quality/Dust (Total Suspended Particulates – TSP) level and Environmental Noise level measurement. It is believe that the environmental monitoring will be widely implemented in other constructions in the future.

Air quality/Dust (TSP) level monitoring

Zero calibration for the dust level monitor

Setting up the meter for sampling

Data record

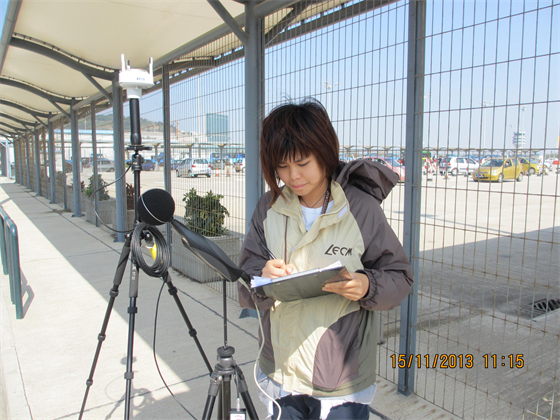

Environmental noise level measurement

Setting up noise level meter

Weather station setting up to collect data of wind speed

Acoustic calibration for sound level meter prior to and following each noise measurement

Data record

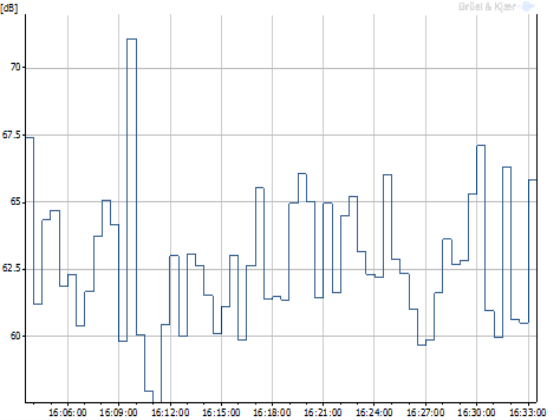

Chart of Noise Monitoring Result (LAeq)

AAR Research Project

Due to the coastal area that the construction situated in Macao, the durability of concrete could be a critical issue of the construction engineering. LECM have implemented the research for the river sand material used in different Macao concrete manufacturers since 2012. The selected test methods of AAR are mortar-bar and concrete prism methods. Besides, LECM have devoted itself to studying the feasible approaches to alleviate the AAR reactivity of river sand as well. The following are the photo examples of this job.

Regular sampling of river sand

Preparation for mortar bar specimens

Preparation for concrete prism specimens

Measurement for specimens

Curing procedure for mortar-bar specimens

Curing procedure for concrete prism specimens

Certification of Cement

Certification of cement product and factory is responsible and conducted by both DMC and DQN. The purpose of this certifi cation is to provide quality assurance for the cement product used in Macao. The criterion of the certification are <Macao Cement Standard> and<LECM’s Rule of Scheme for Certification of Cement>. The certification can be divided into verification of cement factory quality system, initial type test, analysis of factory auto-control test result, verifi cation of conformity cement-regular surveillance, regular sampling of cement product and issue of certifi cation. The following are the photo examples of this job.

Audit meeting

Audit for the laboratory environment

Audit for the test procedure

Audit for the cement production

Audit for equipments

Regular sampling of cement product

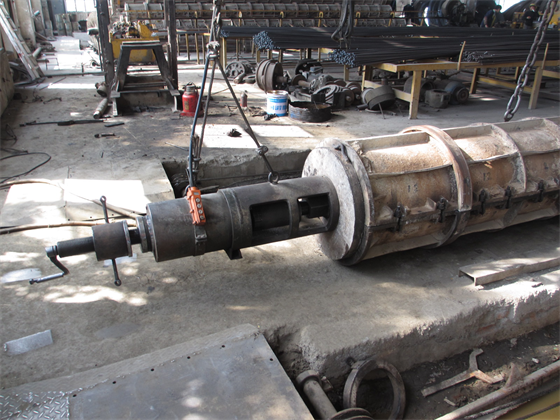

Certification of PHC-pile

Certification of PHC-pile is jointly participated by DMC and DQN. Factories, which have obtained certifi cation, comply with the quality management system and technical requirements specified in the Rules of Scheme for Certifi cation. The purpose of certifi cation is to verify whether factories have the ability to manufacture products that comply with Macao Concrete Standard and the Reception Procedure of PHC-pile.

Appearance check

Raw materials sampling

Rebar cage inspection

Rebar cage inspection

Pretensioning check

Pretensioning check

Mould spinning check

Core sampling

Material test

Bending test

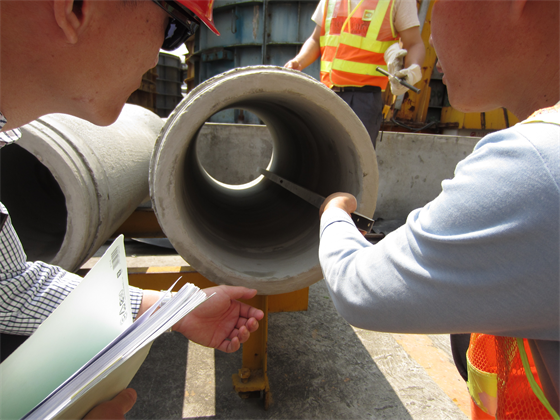

Certification of Concrete Pipe

Certification of concrete pipe is jointly participated by DMC and DQN. Factories, which have obtained certifi cation, comply with the quality management system and technical requirements specifi ed in the Rules of Scheme for Certifi cation. The purpose of certifi cation is to verify whether factories have the ability to manufacture products that comply with specifi ed standards.

Hydrostatic test

Hydrostatic test

Appearance check

Dimensions check

Straightness check

Load test

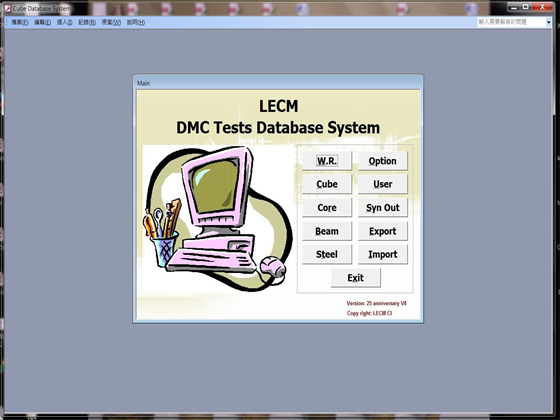

Database for Test Data

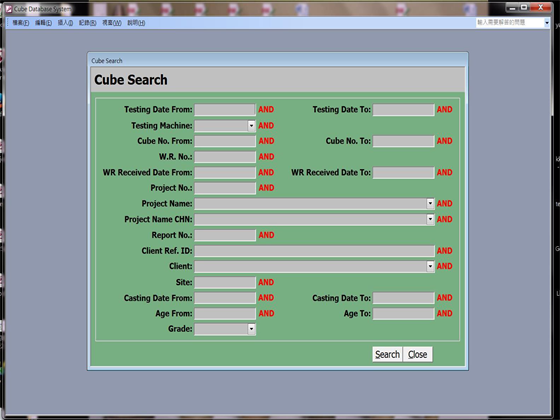

To increase efficiency in the production report, to improve the accuracy and confidentiality, DMC has established a database test data for linking it with testing operation, test report preparation and data processing. The main process is the sample administrator receiving samples, the technician entering sample data, the technicians operating test, then test data is automatically imported into the database and test report is being prepared. During this process, the personnel will be controlled by access rights. Currently, the data base is being used for handling tests of concrete cubes, concrete prisms, steel bar, etc. The application of this data base will subsequently be extended to other tests, such as steel bolt test, steel article test, coating testing, geotextile test, drain cover test, concrete trial mix verifi cation.

Data base interface

Data base interface

Sample register

Data input

Data input

Data processing of test

Verifying

Report preparation